ABOUT:

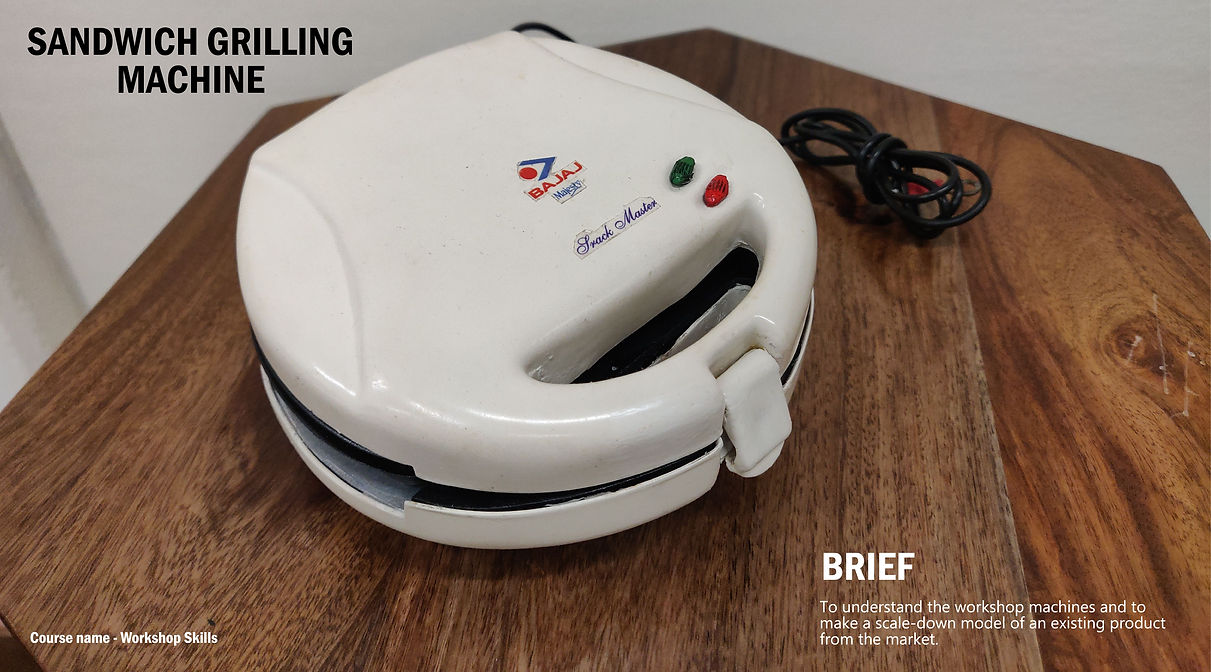

Sandwich grilling machine.

The Final product is a scaled-down model of the Bajaj Sandwich grilling machine of BAJAJ. The main aim of this project was to understand and observe very minute details and manufacturing details to understand design and engineering which goes hand in hand.

Processes

Mdf moulds of the Outter surface of the machine, grilling plate and the stand of the machine, made keeping in mind the curvature, angle of depression and the minute details.

Vacuum moulding done from the mdf moulds.

Taking care of every minute details was challenging and learned about the large scale manufacturing processes and the ergonomic factors.

Comparision of the scaled-down model to the real sandwich grilling machine.

Materials and Manufacturing

Materials and manufacturing is a interactive course aimed to learn and understand the properties of the material and how a final products is made on a large and small scale as it goes through number oftreatments and process based on its nature and reactivity with other material. But we had a different approach of learning this as we experimented.

Paper Exploration

Different techniques such as origami, folding , crushing fusing of two different paper, quilling, rolling and may more techniques were used and disused in the class in order to understand the basics and how we use the properties of the paper to.need. I experimented the making of paper with adding of rice and paper Mache in order to see how it behaves.

Wood Joinery and Inlay

Wood is a porous fibrous structure from the stems and roots of the tree. An assignment to do half dovetail joint. The task was to imitate joinery on a wood piece which looked simple but was tough to do as we were not allowed to use any machines. We also did inlay work in the wood. We tried with metal wires, electrical wires, threads and also tried applying pop to it. Wood requires a lot of patience as it is a subtractive material making us more and more conscious.

Musical Instruments

Materials used in the were mdf, metal, bamboo, rubber bands, glass, metal strings, pvc pipes were used in creating sounds. On the first stage I tried to see what kind of materials would help me produce sound so I tried with bamboo, wood (scooping the inner surface ) which eventually didn’t work ,but found my mistake .This was very important way of learning multiple material interacting with each other based on their properties.

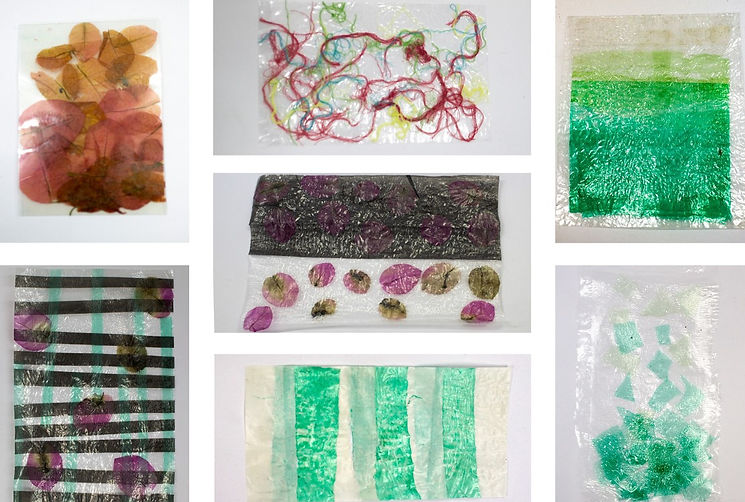

Plastic fussing

Plastic fussing is a simple process and has a variety of results. Working with different grade plastics with varying thickness finding out how the plastic shrinks and fuses with other plastic. Observing some of them giving flat matt finish and some with a curvy gloss finish.

Concrete casting

To have cement mould with a fine finish, MDF mould was made to cast it in silicon liquid to have the negative portion, Later the cement was poured to have the final product.